Major supplies a comprehensive range of equipment for the metals industries. From melting and treating through to scrap metal reclamation for either batch or continuous plants.

In addition to its own technology, Major is able to supply a wide variety of equipment through a network of technology partners.

- Steel Strip Annealing Furnaces and Equipment

- Steel Strip Rapid Jet Cooling

- Steel Abrasive Cut Off and Grinding Machines

- Aluminium Siphoning Systems

- Melting and Holding Furnaces (Large Scale)

- Scrap and Salt Processing and Feeding

- Atmosphere Heat Treatment Furnaces

Tilting Rotary Furnaces

Tilting Rotary Furnaces

Applications

- Aluminium Dross Recycling

- Aluminium Recycling

- Lead Battery Reclaim

- Zinc Dross Recycling

- Light Metal Processing

Benefits over Conventional Non-Tilting Rotary Furnaces

- Faster, safer metal & slag tapping practices

- Lower noise emissions

- Reduced cycle times

- Greater thermal efficiency

- Reduced flux requirements

- Quicker charging sequences

- Reduced labour requirements

Equipment Description

The furnace comprises a refractory lined rotating cylinder, swing aside charge door with integral burner and flue, tilt cradle, stationary floor mounted supports, tilting fume hood and control cabinet.

Furnace Construction

Charging and discharging are both achieved through an opening in the front of the furnace. The charge/discharge door houses the burner and flue which allows the flue gases to attain a double pass. Opening is actuated via a hydraulic actuator which moves about a pivot located to the side. This requires only one position for flexing of the gas, air and electrical cables and results in the furnace door moving to one side with a total rotational travel of 180 degrees.

Furnace Waste Gas Ducting

The flue canopy is directly mounted on to the tilt cradle with the duct terminating on the pivot axis so that fumes may continue to be extracted via a rotating joint throughout the full range of tilt. The flue duct battery limit is a stationary flange at the rotating joint. This system requires an induced exhaust fan downstream of our battery limit.

Electrical Cabinet

The electrical control cabinet has an environmental rating of IP55 and is engineered to be mounted either adjacent to or remotely from the furnace. The electrical battery limit is the cabinet mounted electrical isolation device.

Combustion System

The gas train components have an environmental rating of IP54. The combustion air blower is fitted with noise attenuation on the inlet to reduce noise levels to 83 dBa at 1 metre.

Oxygen / Fuel Combustion

Major’s oxygen enriched combustion system provides customers with an advanced method of processing metals. Our proprietary PLC program provides for tailored cycle parameters to optimise metal recoveries.

Safety

Floor mounted personnel protection guard rails can be provided which are engineered to the Australian Standard and are adjacent to moving parts outside frame support and around hot areas. Guards are provided across the driven end near the rotating motor, and beside the furnace on each side, protecting personnel from the door opening.

Rotary Furnaces

Rotary Furnace – Fixed Axis

Applications

- Copper Lead or Zinc Smelting

- Gold Smelting

- Aluminium Dross or Scrap Recycling

Benefits

- Traditional Process

- Economic furnace configuration

Equipment Description

The furnace comprises a refractory lined cylinder, swing aside charge door, rear mounted burner and flue, rotary cradle and roller bearings, stationary floor mounted support, fixed fume hood and control cabinet.

Furnace Construction

Charging occurs through an opening in the front of the furnace. The liquid metal discharge occurs through a pour spout mounted in the mid section of the main refractory lined cylinder. When the charge door is closed the front section is a close fit to the main rotating body thus leakage of the flue gases during normal operation is minimised.

Refractory Lining

The refractory lining is of a high quality, abrasion resistant brick and castable, backed up with high density insulation board. The charge door is lined with a dense hot face castable and an insulating backup.

Furnace Waste Gas Ducting

A fixed flue canopy is directly mounted above the charge door. The flue and canopy for this type of furnace is normally supplied by the ventilation contractor. This system requires an induced exhaust fan downstream of our battery limit.

Electrical Cabinet

The electrical control cabinet has an environmental rating of IP55 and is engineered to be mounted either adjacent to or remotely from the furnace. The electrical battery limit is the cabinet mounted electrical isolation device.

Combustion System

The fuel train components have an environmental rating of IP54. The combustion air blower is fitted with noise attenuation on the inlet to reduce noise levels to 83 dBa at 1 metre.

Safety

Floor mounted personnel protection guarding can be provided which are engineered to the Australian Standard and are adjacent to moving parts outside frame support and around hot areas. Guards are provided around the mechanism pinch points, and beside the furnace on each side, protecting personnel from the door opening.

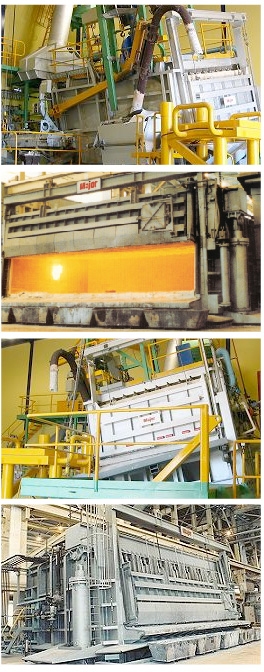

Reverberatory Furnaces

Reverberatory Furnaces

Application

- Aluminium Smelters

- Diecasting Foundries

- Extrusion Foundries

- Secondary Aluminium Foundries

Benefits over Conventional Reverberatory Furnaces

- Advanced refractory design and installation

- Reduction of metal loss using air pressure control systems

- Automated operations by PLC control systems

- Advanced combustion system design and selection

- Lower noise emissions

- Greater thermal efficiency

Equipment Description

Our reverberatory melting and holding furnaces are typically tilting furnaces, natural gas fired, heated by a dual burner system comprising of a primary modulation burner for holding and a secondary burner for melting (dual fuel and electrically heated furnaces also available on request).

Furnace Construction

The furnace is a robust rectangular shaped unit with flat roof (other shapes also available), engineered for reverberatory heating of a molten metal charge. Our furnaces have a wide main door to facilitate both scrap loading and furnace cleaning. They are solidly built, particularly around the door surrounds to minimise warpage and loss of door sealing. Tilting of the furnace is actuated via twin hydraulic cylinders mounted between the tilting cradle and the stationary frame, with the pivot axis close to the pour point. The furnace is capable of tilting to allow the removal of all furnace contents.

Refractory Lining

This refractory lining comprises typically 230mm of 85% Alumina phosphate bonded refractories below the metal line backed up by insulating refractories for optimal wear characteristics.

Major also has the capability to re-engineer furnace refractory linings to accommodate new requirements such as siphoning systems or increased furnace capabilities.

Electrical Cabinet

A free-standing operator control panel of IP54 rating is provided to house the control equipment for the furnace. The PLC which is used to control the furnace operating parameters is typically housed in a separate control room or alternatively can be located in the main control cabinet.

Combustion System

The furnace typically has two nozzle mix burners with high turndown capacity and medium to high velocity flame to assist in good heat transfer. Burner controllers and over-temperature safety instruments are located in the operator control cubicle together with all necessary pushbuttons, indication lights, relays, etc. for the safe operation of the plant.

Air Pressure Control System

Furnace pressure is monitored by pressure transmitter and controlled by PLC PID loop. The furnace pressure is maintained at slightly positive to minimise ingress of cold air and hot egress and hence maximize fuel efficiency

Furnace Sizes

Major supplies an extensive range of reverberatory melting and holding furnaces with capacities ranging from 1 tonne to 80 tonnes. Others available on request.

Siphon Systems

Siphon Systems

Applications

- Siphon Transfer of Liquid Aluminium from transfer crucibles to aluminium holding furnaces

- Other Applications on request

Benefits Over Conventional Transfer Methods

- Safer molten metal transfer practices

- Reduction of metal loss of around 75% of dross make due to the hot metal transferring operation

- Automated vacuum control system utilising PLC

- Low residual of aluminium remaining in transfer crucibles

Equipment Description

Major is licensed by Rio Tinto Alcan Limited to manufacture and sell Siphon Systems for transferring molten metal from transfer crucibles into holding furnaces. Siphon Pipe Design, PLC controlled vacuum system, siphon raise – lower systems are all covered by this license.

Rio Tinto Alcan, who manage primary aluminium smelters at Boyne Island and Bell Bay in Australia and Tiwai Point in New Zealand, together with Major, have jointly developed siphon pipe handling systems, their structures and the lifting and lowering mechanisms.

Tests with the fully operational system have demonstrated a reduction of some 75% of dross make due to the enhanced, non-turbulent flow achieved through siphon metal transfer.

The siphoning system is a PLC controlled vacuum system which transfers metal via a siphoning method from one bath of liquid metal to another.

The Main Elements of the System: PLC Controlled Vacuum System

The system incorporates a PLC system to control the vacuum which enables metal to be transferred at set flowrates through the siphon pipe.

Siphon Lifting Mechanism

- Provides concise alignment of siphon pipe into the furnace

- Permits clear vehicle clearance when siphon pipe is parked

- Safety latch mechanism retains the siphon pipe in parked position

- Enables the operator to have clear view of siphon pipe during raising and lowering

Siphon Roller Post

Guides siphon pipe into furnace port.

Siphon Pipe Heating System

Pre-heat burner on post heats siphon pipe raised in parked position.

References

The Rio Tinto Alcan siphoning system is installed at the following primary aluminium plants:

- Boyne Smelters, Queensland, Australia

- Sohar Aluminium, Sohar, Oman

Complementary Technologies: Crucible Tilting System

Can be used to enable the transfer crucible to be tilted adjacent to the holding furnace, freeing up the crucible transfer vehicle to transport other crucibles during siphoning.

Siphon Pipe Cleaning System

An essential part of the system which can be supplied by Major.

Siphon Pipe Transport/Changeover Vehicle

- Single operator siphon pipe changeover

- Delivers clean siphon pipe and changes used pipe in single setup

- Clamps used pipe and transports to cleaning station

- Moves clean siphon to roller post station

- Safe and quick siphon pipe changeover

Tilting Crucible Furnaces

Tilting Crucible Furnace

Non Ferrous Applications

- Aluminium Melting

- Gold Melting and Refining

- Lead an Zinc Melting

- Copper, Brass and Bronze Melting

Design Features

- Hydraulic Lip Axis Tilting

- Wide range of fuels useable

- Low thermal losses – high efficiency

- Silicon carbide crucible as standard

- Special applications built to order

Equipment Description Construction

Major crucible melting furnaces are of steel fabricated construction using plate and rolled sections. The furnace is lined with high temperature rated refractory, backed with calcium silicate insulating board.

Temperature Control

Standard temperature control is achieved by sensing flue gas temperature which is shown on a digital display.

Bath Temperature Control (Optional)

An immersion thermocouple in a protective sheath can be used to sense actual melt temperature. This optional extra is supplied with an LED display of set and operating temperature.

Control Panel

Features include:

- Digital display of temperatures

- Power on indicating light

- Main isolating switch

Safety Features

In case of accidental spill of metal or failure of crucible within the furnace an emergency plug fitted in the base would automatically dislodge, thus allowing molten metal to escape from within.

Burner

The two stage packaged type burner is complete with built in fan, flame safety controls and electric ignition. The burner, when not operating, is protected against radiant heat from refractory by a thermostat activating the fan to maintain burner internals within acceptable temperature limits.

Bale Out Crucible Furnaces

Bale Out Crucible Melting Furnaces

Applications

- Aluminium Die Casting

- Aluminium Sand Casting

- Aluminium Gravity Casting

- Laboratory Metal Melting

Design Features

- Wide range of fuels useable

- Low thermal losses – high efficiency

- Silicon carbide crucible as standard

- Special applications built to order

Equipment Description Construction

Major crucible melting furnaces are of steel fabricated construction using plate and rolled sections. The furnace is lined with high temperature rated refractory, backed with calcium silicate insulating board.

Temperature Control

Standard temperature control is achieved by sensing flue gas temperature which is shown on a digital display.

Bath Temperature Control (Optional)

An immersion thermocouple in a protective sheath can be used to sense actual melt temperature. This optional extra is supplied with an LED display of set and operating temperature.

Control Panel

Features include:

- Digital display of temperatures

- Power on indicating light

- Main isolating switch

Safety Features

In case of accidental spill of metal or failure of crucible within the furnace an emergency plug fitted in the base would automatically dislodge, thus allowing molten metal to escape from within.

Burner

The two stage packaged type burner is complete with built in fan, flame safety controls and electric ignition. The burner, when not operating, is protected against radiant heat from refractory by a thermostat activating the fan to maintain burner internals within acceptable temperature limits.

Electric Resistance Heating

Banks of electric elements of nickel chrome alloy held in ceramic supports surround the crucible providing the necessary energy to melt the charge.

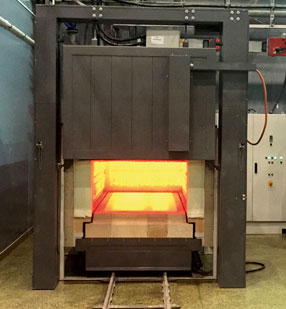

Heat Treatment Furnaces

Major can supply a variety of Heat Treatment Furnaces for industrial processes including steel, non-ferrous metals, plastics and carbon fibre materials, these include:

- Bogie Hearth Furnaces

- Air Circulation Furnaces and Ovens

- Retort Chamber Furnaces

- Annealing and Hardening Furnaces

Laboratory Furnaces

Major can supply a variety of Laboratory Furnaces for research, industry and dental sectors, these include:

- Annealing

- Hardening

- Tempering

- Carburzing

- Nitriding

- Retort Chamber