Major Refractory Services has been involved with the engineering, maintenance and installation of refractory and wear lining systems for over 70 years. We maintain a nucleus of skilled refractory craftsmen to ensure our high standards are maintained. We have extensive experience in “non-wetting” aluminium contact, waste incineration linings and wear linings for process plant.

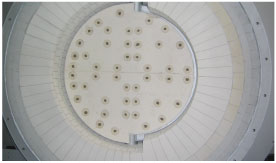

Detail Engineering and InspectionSince refractory linings are the heart of a furnace, Major applies its accumulated knowledge into providing technical solutions for multi-layered refractory linings.

Onsite MaintenanceMajor can provide turnkey installation and maintenance on a small to medium scale for various materials, from tapping blocks to a plant.

Major can provide full refractory and wear lining repairs and rebuilds of basic and specialised components. Utilising in-house plant and machinery, Major can assemble, finish and cure to high temperatures a wide variety of components which include:

- Hot Gas Dampers

- Zinc and Zinc/Aluminium mixture Inductors

- Tapping Blocks

- Burner Panels

- Launders

- Zinc and Zinc/Aluminium mixture Pre-Melt Pots complete

- Furnace Doors

- Waste Gas Stacks

- Transfer chutes

- Specialised castings to your requirements